Fundamental concepts of PP Sheet

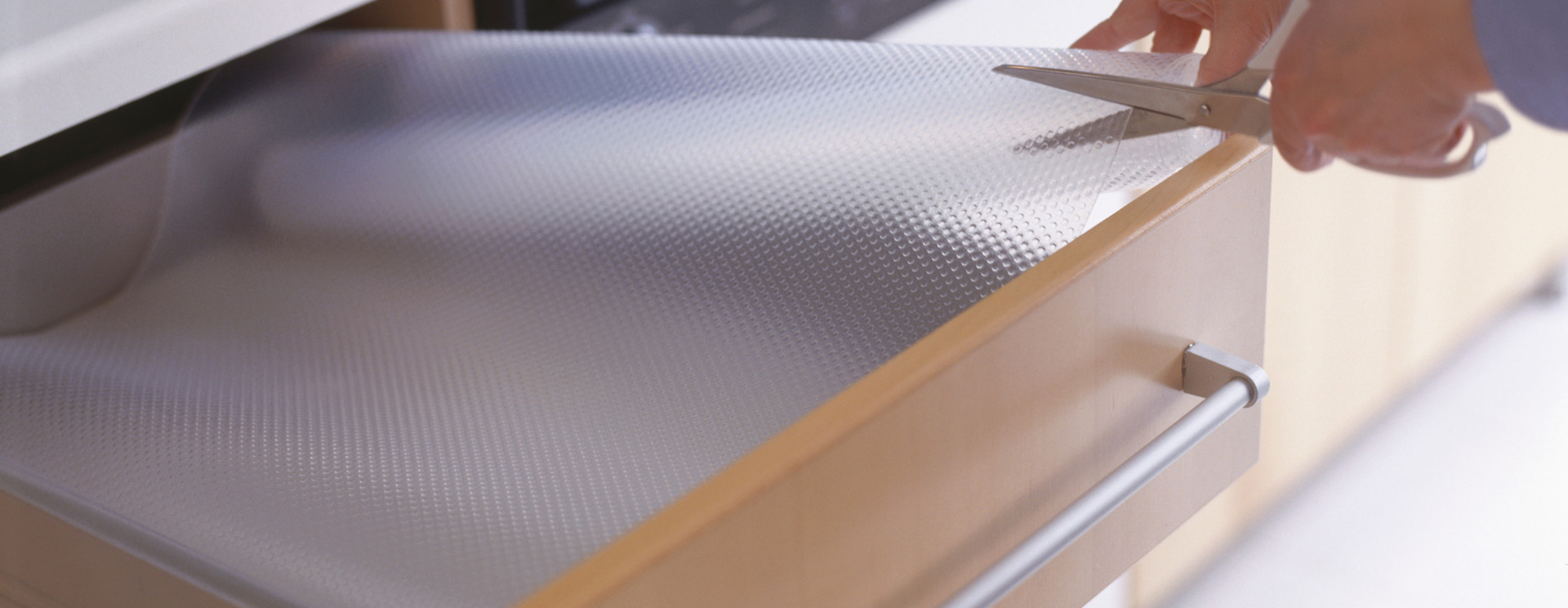

Polypropylene sheets have comparable qualities to ABS plastic and HDPE in light of the fact that they are synthetically related. In contrast with other polymer sheeting materials, polypropylene sheeting has a respectable power proportion and medium strength. It offers a superior blend of compound, electrical, and warm characteristics and is reasonable for microorganisms' circumstances because of the great, strong floor.

Despite the fact that polypropylene sheeting isn't UV-secured, it is USDA-approved and fulfills FDA prerequisites. Among the main benefits of utilizing polypropylene sheeting rather than ABS or HDPE sheeting is its adaptability to structure, weld, and twist. Polypropylene is also strong and has excellent erosion resistance, scrape resistance, and impact strength. Pay special attention to the contorted polypropylene sheets for additional plastic sheeting choices. PP sheets are a versatile polymer that is used for a variety of applications requiring compound and consumption strength, high effect resistance, and a maximum strength proportion. These qualities make polypropylene an exceptionally sought-after material for many ordinary and modern purposes.

Plastic is, nonetheless, one substance that is very adaptable and utilized in different ventures. Providing a different scope of plastic-made merchandise is a technique for enchanting shoppers from different businesses. "Polycan Extrusion Pvt. Ltd." is the manufacturer and distributor of high-thickness polyethylene sheets, straightforward PE sacks, woven blockade tape rolls, polyethylene psychologist wrap films, PP seepage cell mats, and other items. These plastic-made items are used for walls, link security, pipe safety, shrink wrap, pressing, and a variety of other applications. Top-notch plastic is being utilized to make the above items in the best examples and styles.

Polypropylene Sheet Benefits:

1. PP sheets are extremely light in weight, with a grouping of just 0.91 g/cm3, and are plastic that genuinely suspends, which can help with taking care of where gear is required to be utilized.

2. Polypropylene sheet has a really diminished ingestion of dampness, at 0.03, which can improve merchandise and component security and help with safe microbes.

3. Polypropylene sheet has great corrosive and synthetic solidity, making it helpful in the production of modern and corrosive tanks as well as safe scraped area terminations.

4. Polypropylene sheet can also be quickly framed, molded, and vacuum-formed, allowing it to be used in the development area and make higher things required in many industries, including automobiles.

5. Polypropylene sheet is also very clever because it can achieve the same results as different parts at a much lower cost.

6. Polypropylene Sheet is nearly impossible to reconnect with current cements; however, future glues in this area may fix these issues; for the time being, polypropylene can be patched utilizing simple welding bars and metalworking bars.

For More Info:-